DIES

A cold sheet metal die is a tool designed to deform or cut metal sheets without the use of heat, relying on the force applied by a press.

This tool is widely used in the industrial sector to produce metal components with specific shapes quickly, precisely, and repeatedly.

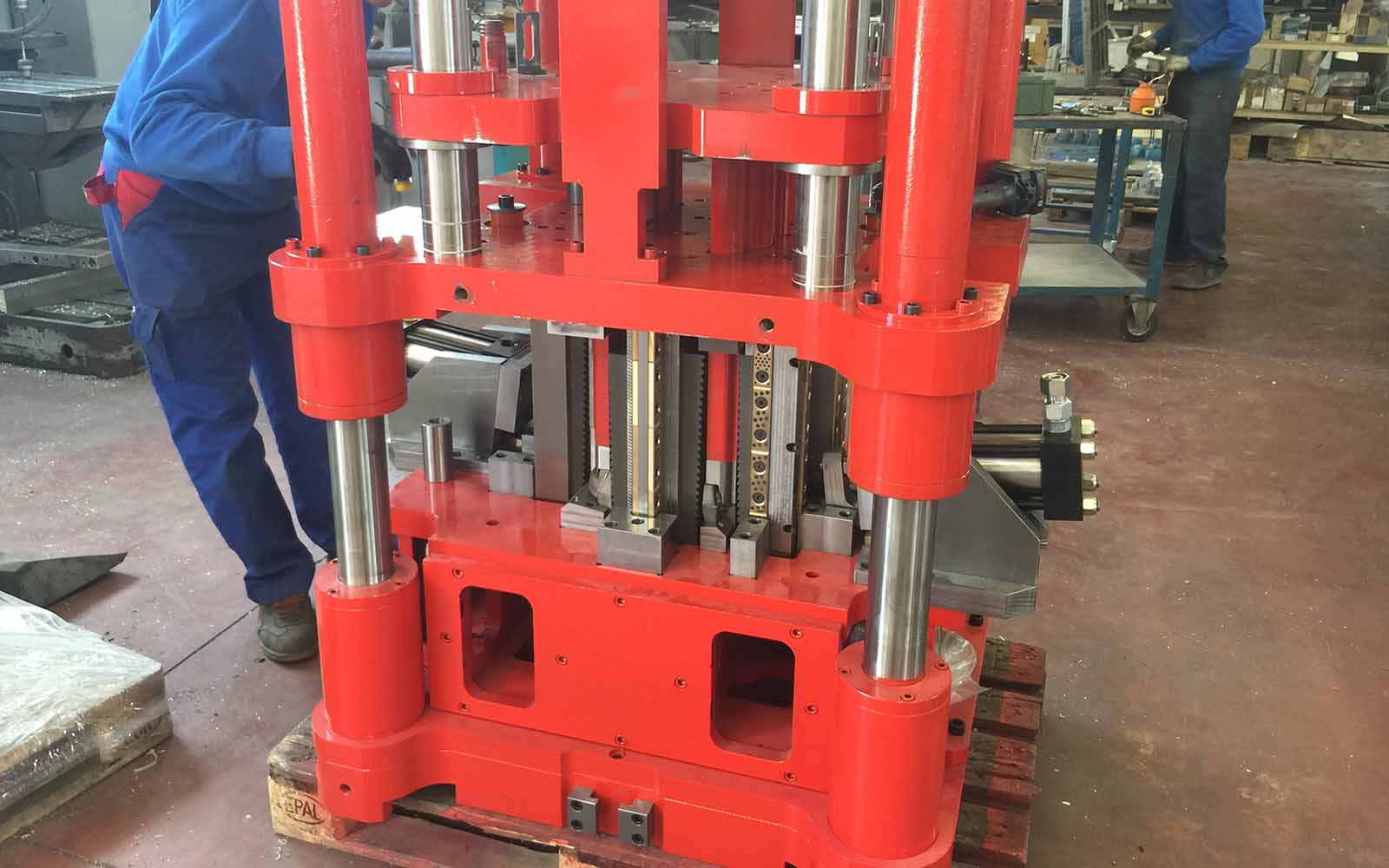

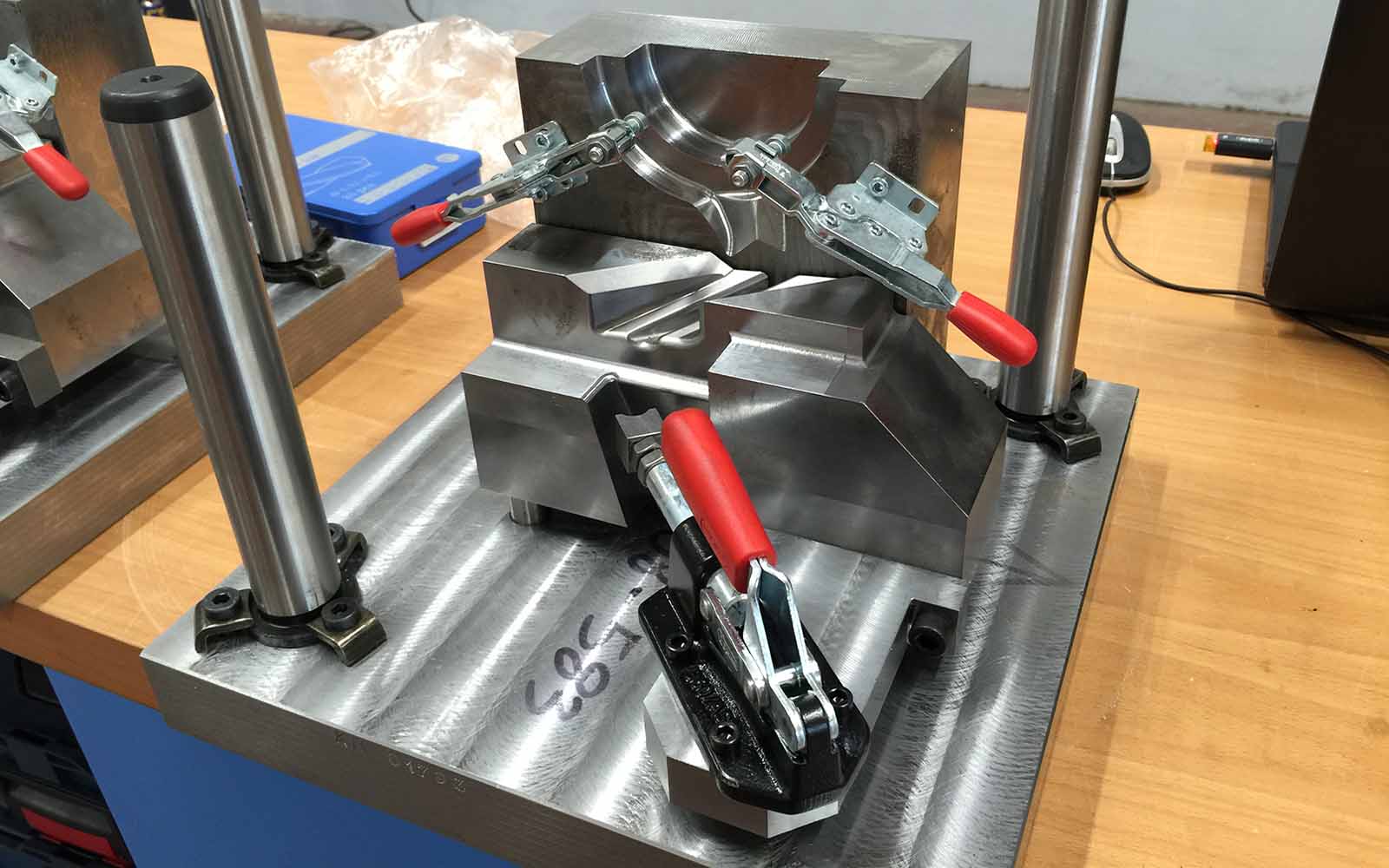

DIE STRUCTURE

A die is generally composed of two main parts:

- Upper part (punch):

The movable part of the die that applies the necessary force to deform or cut the sheet metal. - Lower part (die):

The fixed part that supports the sheet metal and guides the punch during the process, giving the piece its desired shape.

Other common components include:

- Guides: Ensure precise alignment between the punch and the die.

- Springs or return systems: Allow the die to reset after the operation.

- Fastening elements: Secure the die to the press.

TYPES OF DIES

Cold sheet metal processing dies can be classified based on the type of operation:

- Blanking dies:

Used to cut the sheet metal into a specific shape. - Bending dies:

Designed to bend the sheet metal at defined angles. - Deep drawing dies:

Deform the sheet metal to create curved surfaces or cavities, such as metal containers. - Progressive dies:

Perform multiple operations (blanking, bending, etc.) in an automated sequence through successive stations. - Combination dies:

Simultaneously carry out multiple operations (e.g., cutting and bending).

FUNCTIONING

- Preparation:

The sheet metal is positioned on the die, often using an automated feeding system. - Press action:

The press pushes the punch toward the die with enough force to deform or cut the sheet metal. - Piece formation:

The interaction between the punch, die, and sheet metal gives the material its desired shape. - Piece removal:

The processed part is extracted manually or automatically, leaving the die ready for the next operation.

ADVANTAGES

- High precision:

Achieves components with very tight tolerances. - Repeatability:

Ensures uniformity in mass-produced parts. - Efficiency:

Reduces production time compared to other techniques. - Versatility:

Can be used with different materials and complex shapes.

APPLICATIONS

Automotive industry

Production of car bodies, frames and metal components.

Home appliances

Manufacturing of casings and structural parts.

Building sector

Production of metal panels and accessories.

Aerospace sector

Creating lightweight, durable metal components.

In summary, a cold sheet metal working die is an essential tool for industrial manufacturing, offering an ideal balance between precision, speed and scalability in the forming and cutting processes.