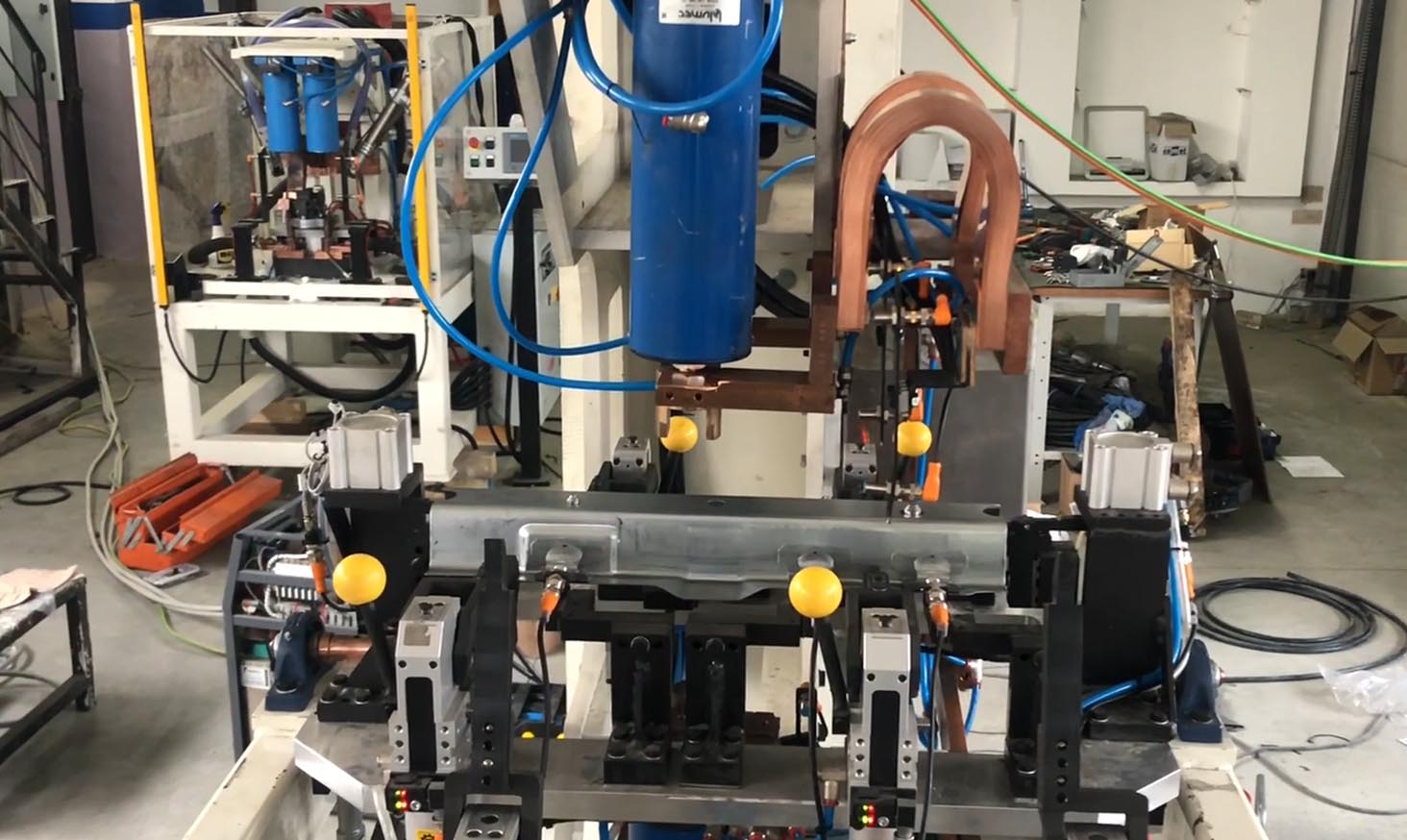

SPECIAL SPOT WELDING MACHINES

A special spot welding machine is an industrial equipment designed to perform spot welding in a highly customized manner, adapting to specific production requirements. This technology is used to join two or more metal sheets by applying heat and pressure at precise points, utilizing the electrical resistance of the materials.

MAIN FEATURES

- Customization:

A special spot welding machine is tailored to a specific production process, considering the geometry of the parts, materials, and production requirements. - Robust structure:

Built to withstand high loads and ensure stability during welding, even in intensive production cycles. - Advanced control systems:

Integrated software and sensors monitor parameters such as current, pressure, and welding time, ensuring precision and quality. - Interchangeable electrodes:

Adaptable to different configurations and materials. - Automation:

Often integrated into automated production lines, featuring automatic loading/unloading systems and synchronization with other machines.

FUNCTIONING

- Electrode application:

Two conductive electrodes are positioned on both sides of the overlapping metal sheets. - Current flow:

A high-intensity electric current passes through the electrodes, generating heat via Joule effect at the contact point between the sheets. - Metal fusion:

The produced heat melts the materials, creating a localized joint. - Cooling and solidification:

The electrodes maintain pressure while the molten metal solidifies, forming a strong weld.

ADVANTAGES

- High productivity:

Ideal for mass production due to the process speed. - Repeatability:

Ensures uniform joints with consistent quality. - Energy efficiency:

Uses only the necessary amount of energy for each weld point. - Adaptability:

Configurable for different material thicknesses and shapes. - Reduced thermal impact:

The localized welding minimizes thermal deformation of the parts.

APPLICATIONS

Automotive industry

For the welding of frames, panels, and load-bearing structures.

Household appliances

Joining of metal parts for washing machines, refrigerators, and other appliances.

Aerospace sector

For light and durable components.

Light metal carpentry

Manufacturing of metal structures and accessories

ADVANCED CONFIGURATIONS

Portal machines

For welding on large-sized parts.

Robotized clamp machines

Integrated into robotic systems to maximize automation.

Multi-point machines

With multiple electrodes to perform multiple welds in a single cycle.