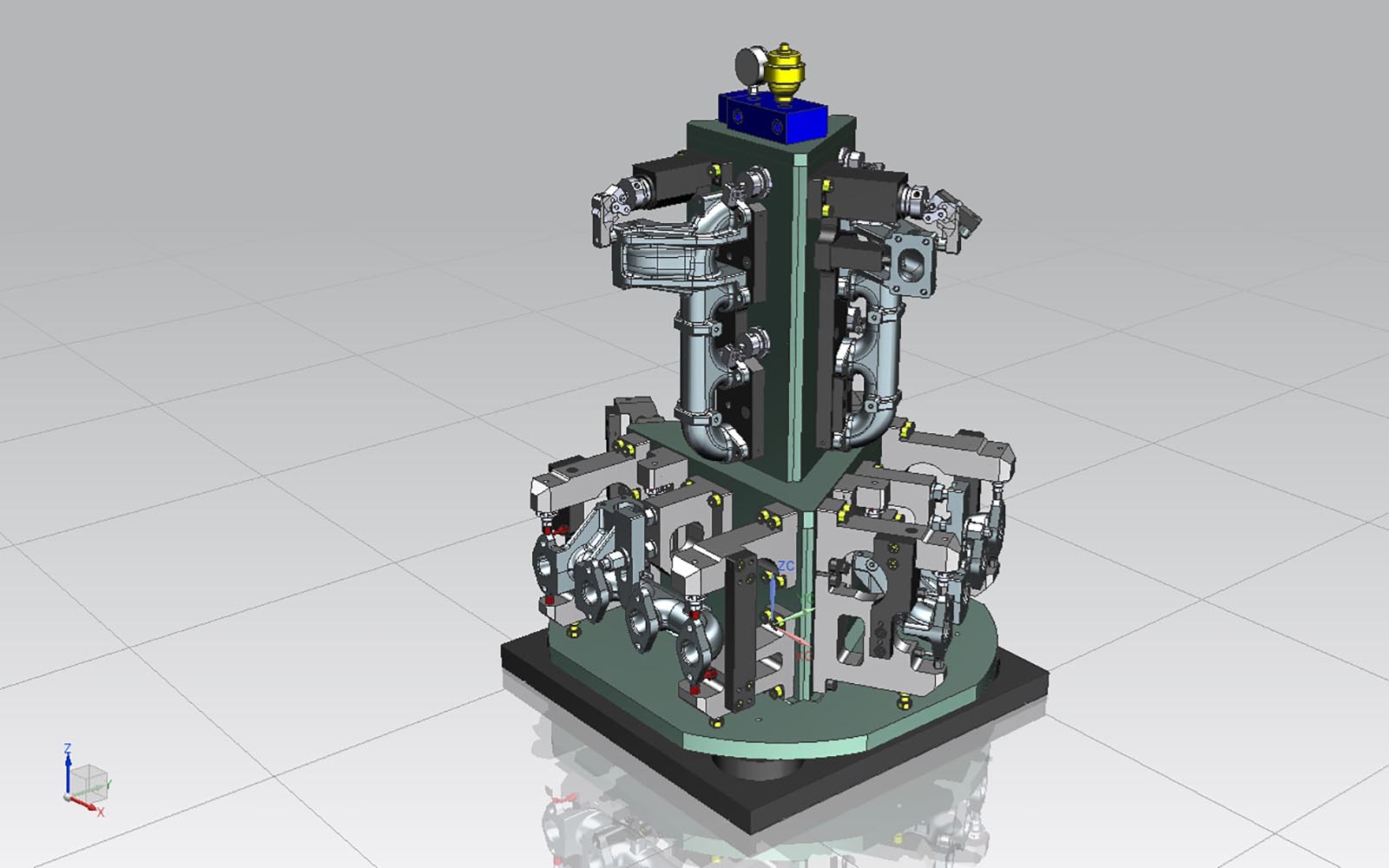

PALLET FOR CNC MACHINING

A pallet for mechanical processing is a rigid and sturdy platform designed for clamping and handling parts during machining processes on machine tools such as milling machines, lathes, grinders, or machining centers.

This device is an essential part of modern automation and production systems, as it helps improve precision, efficiency, and productivity.

MAIN FEATURES

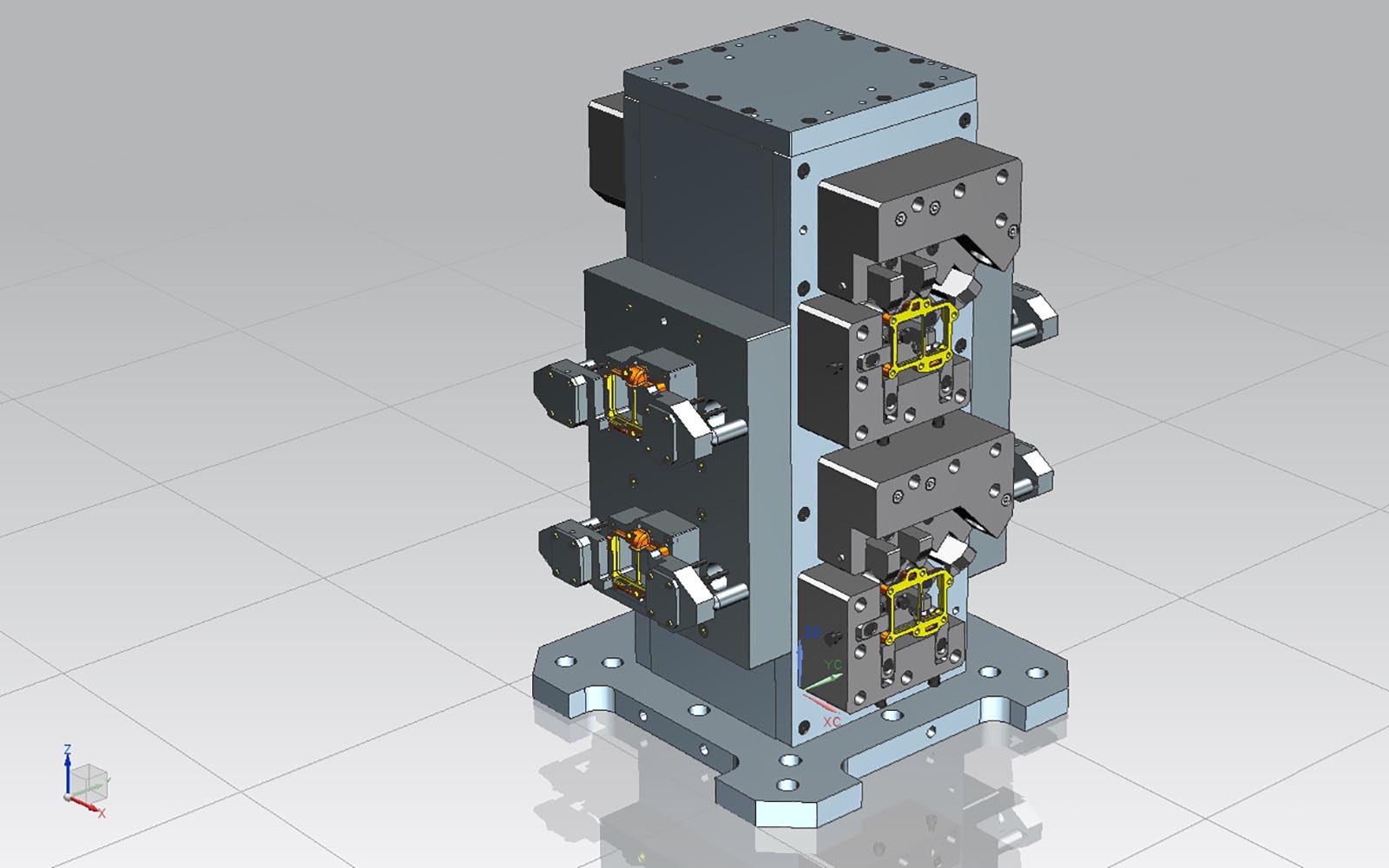

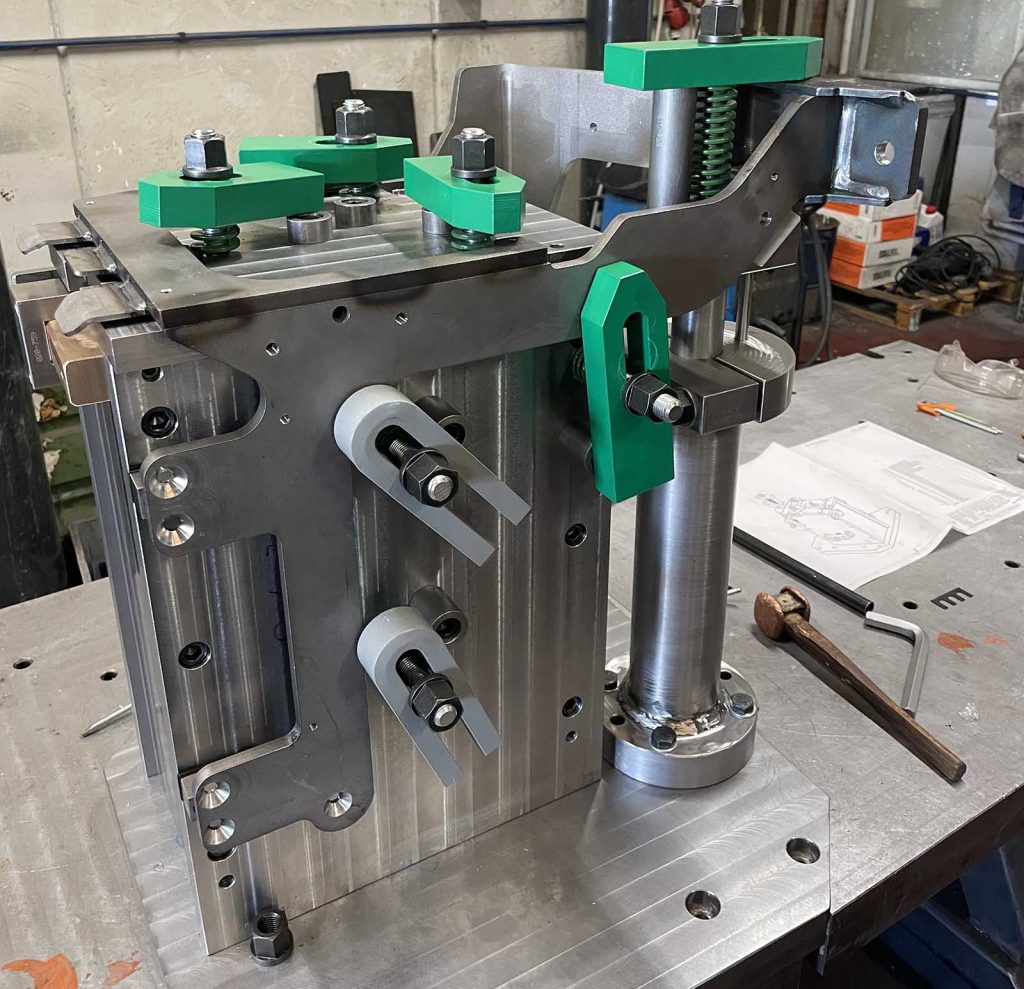

- Material construction:

Made from high-strength materials such as steel, cast iron, or aluminum alloys to ensure stability and withstand the forces generated during machining. - Reference surfaces:

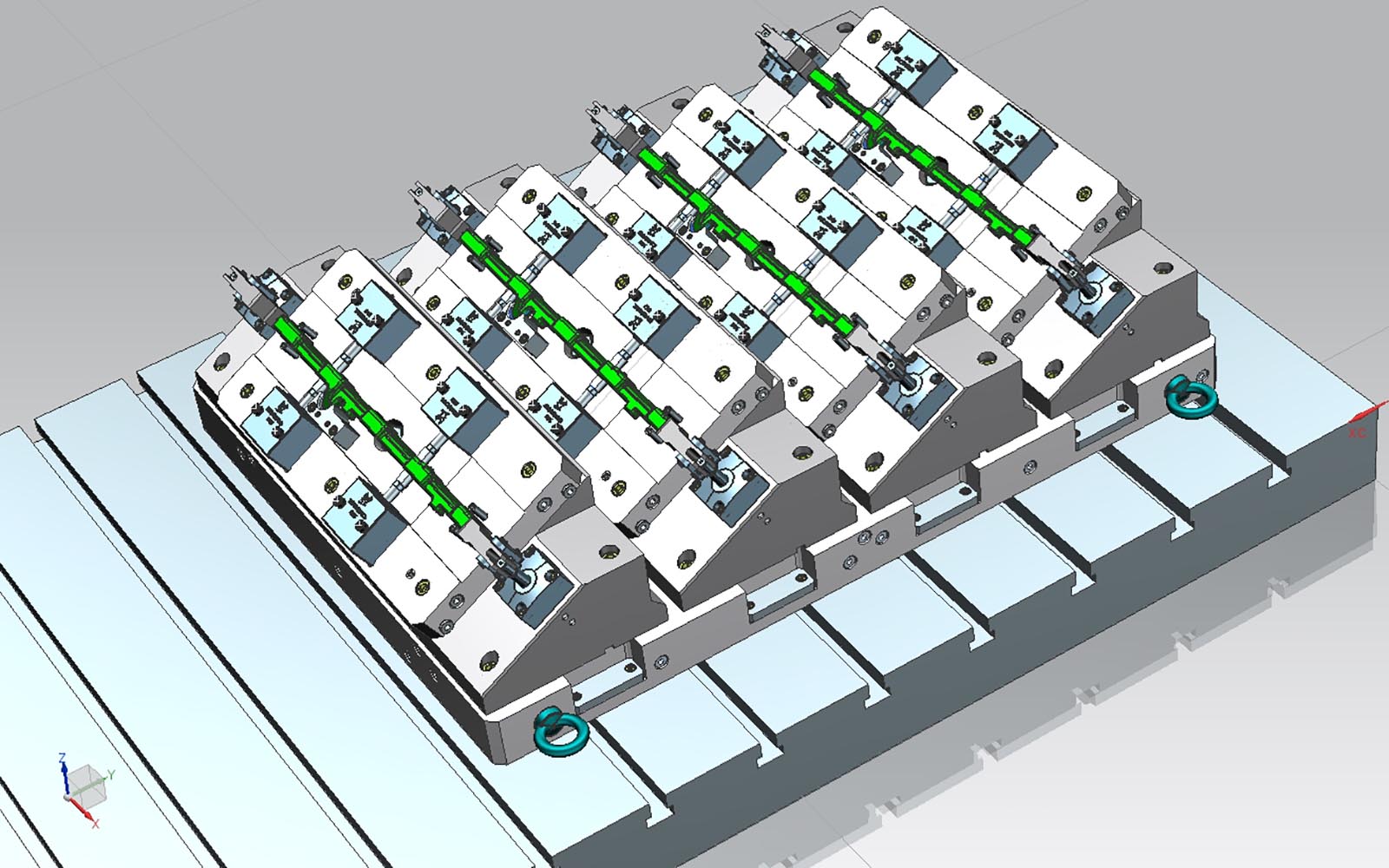

Equipped with guides, holes, or slots for the precise positioning of parts and for clamping using locking systems (manual, pneumatic, or hydraulic). - Modularity:

Designed to adapt to different part configurations, allowing for easy replacement or reuse in different production stages. - Compatibility with automation:

Often used in automatic pallet changing systems, where the pallet is moved between the loading/unloading station and the machine tool without manual intervention.

FUNCTIONING

- Part clamping:

Ensures the part remains stationary and in the correct position during machining, preventing vibrations or unwanted movement. - Positioning accurancy:

Helps maintain tight tolerances by providing precise references for alignment. - Production efficency:

Allows for parts to be prepared outside the machine tool, reducing machine downtime.

ADVANTAGES

- Cycle time reduction:

By preparing pallets in advance, downtime associated with machine setup is reduced. - Versatility:

Suitable for multiple machining operations, such as milling, drilling, or grinding. - Increased productivity:

Promotes automation and the continuous flow of production processes.

APPLICATIONS

Automotive industry

For machining components such as engine blocks, cylinder heads, and transmissions.

Aerospace sector

For precision machining of structural and mechanical components.

Machine tools

For serial or low-volume production.

In summary, a pallet for mechanical processing is a key element in improving efficiency and quality in production processes, facilitating the work of machine tools and ensuring high standards of precision and repeatability.