AUTOMATIC RIVETING SYSTEMS

Automatic riveting systems are industrial solutions designed to perform the riveting process automatically, ensuring the permanent joining of two or more components using rivets.

These systems enhance speed, precision, and efficiency compared to manual riveting, enabling continuous, high-quality production.

MAIN

COMPONENTS

- Loading Station:

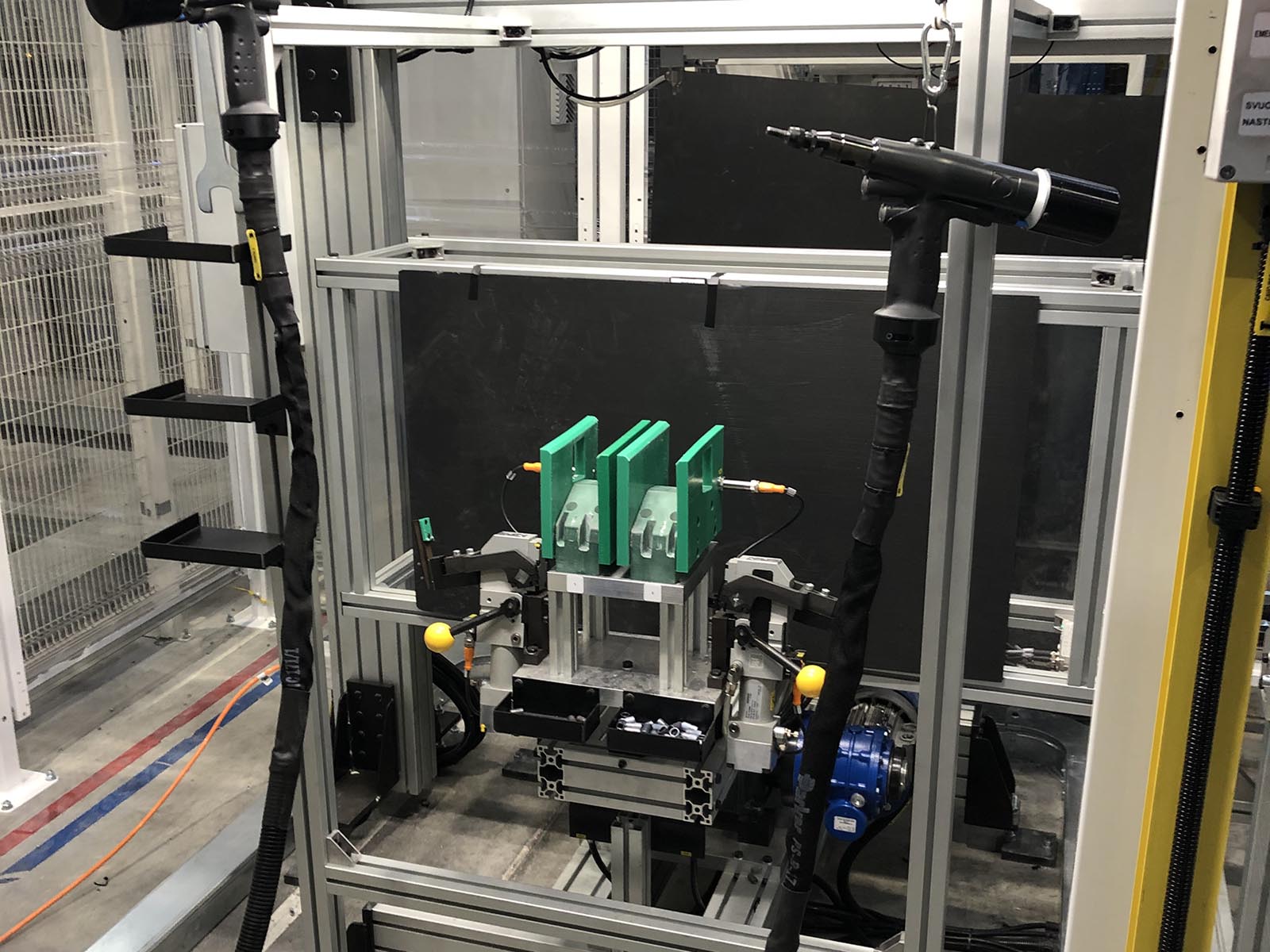

Area where components to be assembled are positioned manually or automatically using robots or conveyor belts. - Riveting Unit:

Includes the rivet feeding and insertion system, the riveting head, and the deformation mechanism to secure the parts. - Handling Systems:

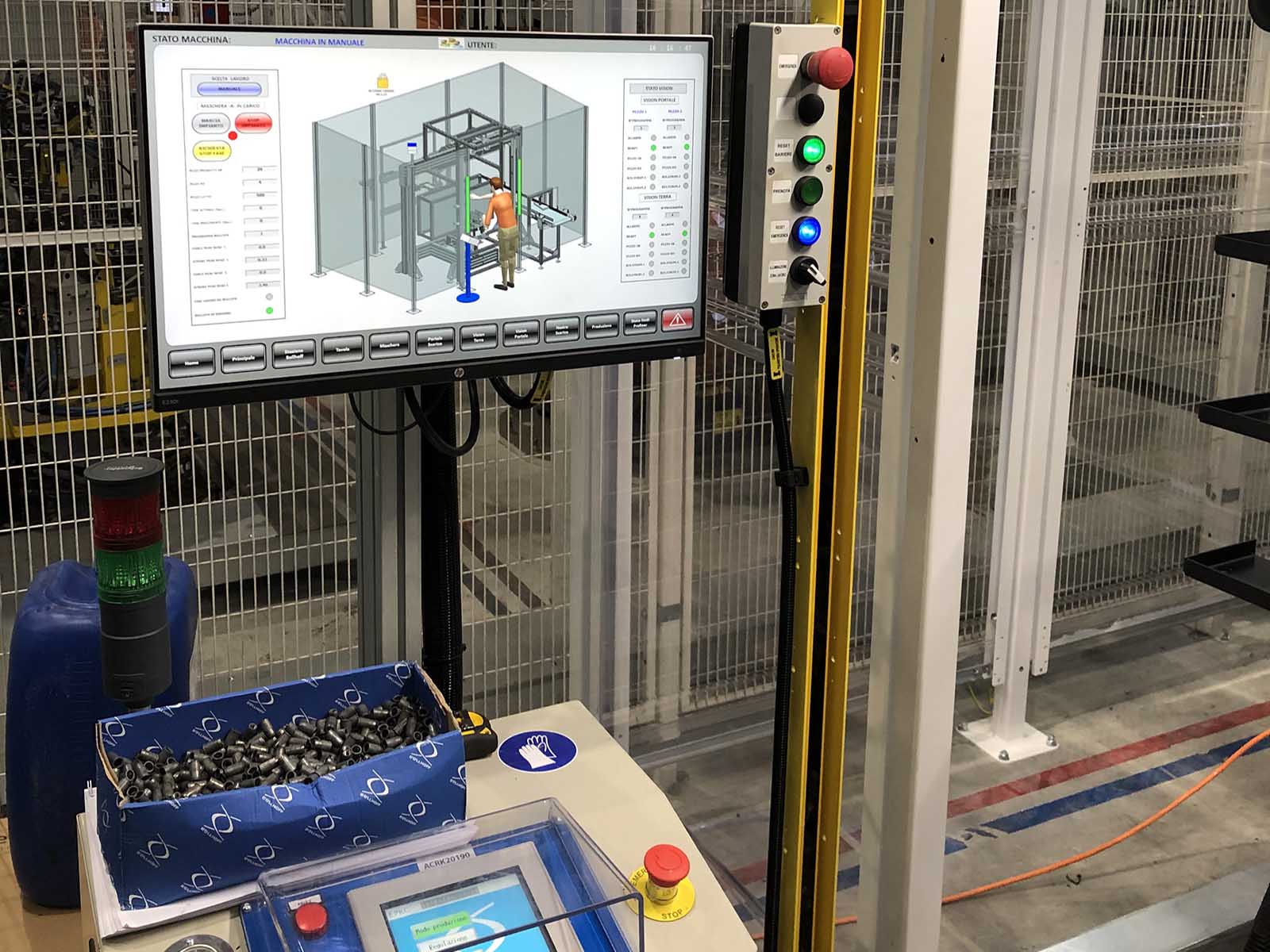

Robotic arms, rotating platforms, or conveyor systems to accurately position components under the riveting head. - Control System:

Advanced software to monitor and manage the riveting process, ensuring proper rivet application and detecting any anomalies. - Safety Devices:

Protective barriers, sensors, and emergency stop buttons to safeguard operators.

TYPES OF AUTOMATIC RIVETING

- Press Riveting:

The rivet is deformed through the application of controlled pressure. - Cold Riveting (Clinching):

A method that joins materials without heating or pre-drilling, often used for thin sheets. - Hot Riveting:

The rivet is heated before deformation, suitable for materials requiring increased malleability. - Radial or Orbital Riveting:

A technique where deformation occurs through controlled orbital motion, ideal for delicate applications.

ADVANTAGES OF AUTOMATIC RIVETING SYSTEMS

- Speed and Productivity:

Ability to perform a high number of riveting operations in a short time. - Precision and Repeatability:

Accurate rivet positioning and uniform application force on each joint. - Reduced Operating Costs:

Less manual intervention and minimized downtime. - Consistent Quality:

Elimination of human errors and assembly defects. - Enhanced Safety:

Reduced operator exposure to handling and assembly risks.

APPLICATIONS

Automotive industry

Assembly of frames, panels, and structural components.

Household components

Fastening of enclosures and internal metal structures.

Aerospace sector

Joining of lightweight yet strong components for fuselages and wings.

Electronic industry

Assembly of casings and chassis for devices.

Metal carpentry

Creation of sheet metal structures for industrial or civil use.

ADVANCED CONFIGURATIONS

Multi-station systems

Designed to perform riveting operations on multiple points simultaneously.

Robotic systems

Integrate robotic arms to position and secure components with maximum precision.

Modular solutions

Customizable to adapt to different product configurations and rivet types.

Automatic riveting systems represent a technologically advanced solution for modern industry, combining automation, efficiency, and quality to meet large-scale production demands.